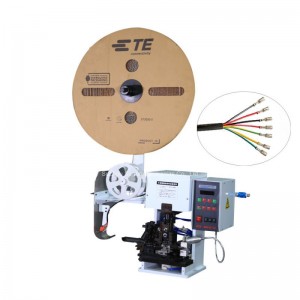

Full automatic wire stripping tinning machine

|

Model |

SA-ST100 |

|

Name |

Automatic double wire cutting stripping terminal crimping machine |

|

Display |

Color LCD touch screen |

|

Blade adjustment method |

Motorized adjusting |

|

Wire cutting length |

45mm-9999mm |

|

Cutting tolerance |

0.20% |

|

Wire crimping length |

1.5-10mm |

|

Suitable wires |

AWG18—28#( Other can customized ) |

|

cutting speed |

1500-4000PCS/hour |

|

Crirmp force |

standard 2.0T(customized available) |

|

Power |

AC 220V |

|

Rated power |

2.5KW |

|

Weight |

320kgs |

|

Size |

1600L*800W*600H |

Our mission: for the interests of customers, we strive to innovate and create the world's most innovative products.Our philosophy: honest, customers-centric, market-oriented, technology-based, quality assurance.Our service: 24-hour hotline services.You are welcome to call us. The company has passed ISO9001 quality management system certification , and has been recognized as municipal enterprise engineering technology center , municipal science and technology enterprise , and national high-tech enterprise .